|

Having

now cover over 2500 miles in AFG 486S,

in one year since it passed the SVA

Test, it was now time to modify some of

the electrics that had give some

trouble.

The first of which was

the original fuse box which I have

used from the Escort MK2. This caused

and total power failure on the

winkers, instruments lights,

stoplights etc. on a run out one

evening.

The fuse box is made of

plastic, with copper fuse holders. The

problem is caused by corrosion between

the holders and connecting pins

riveted through the plastic holder and

you cannot solder or fix it in any

way. The only solution is to scrap the

thing and obtain a new one (rare as

rocking horse poo) or a second-hand

one.

A trip down the local

Ford breakers was in order. They had

six in their bin, two of which were

wired up differently underneath. The

remaining four were the same type as

mine of which only two was good. The

other two had the same problems as

mine so I bought the two goods ones

for a total of £10.00

Back home I plugged the

new fuse box in and have no more

problems up to date.

The second item I wanted

to change was the contact breaker

system on my Ford Crossflow 1300

engine.

On the Bucket & Spade

run in June, the engine had started to

miss-fire and on investigation the

points had closed up. Time to upgrade

to a electronic system.

Looking through the

magazines, they range in all prices

and I remembered an article in the

LOCUST Mag on a Maplin product for

about £ 12.00. I did look at the

product but felt I could go one

better.

I scoured through my

books on Ford parts and found that

Ford went over to electronic ignitions

round about 1981 on the Escort. The

Mk4 1300 Escortís has got a nice Bosch

electronic ignition, not on a CVH

engine, but on a Valencia engine which

is very similar to the Crossflow

fitted to the Mk 1 & Mk2 Escorts,

Cortinas and Capriís.

They are the type with

the amplifier mounted on the side of

the distributor body as in the Fiesta

1.4,Orion 1.3, 1.4, 1.6, & 1.6i,

XR3 & XR3i.

The only problem which

accurse with the amplifier module is

contact with the main body of the

distributors. Take the two screws out

and clean both surfaces. coat then

with special heat conducting compound

available from your Ford dealers and

screw amplifier back on.

What is good, is the

distributor from these will drop

straight in to the Crossflow engine

with a few minor wiring alterations

and change of coil.

Why do you need a change

of Coil?

If you run a Crossflow

engine using the original Ford wiring

loom, it will be ballasted at 9 volts,

and this will not suit the above

distributors. A standard coil of 12

volts will do.

Back down to the Ford

breakers. After searching around, I

found a nice distributor in a Fiesta

1.4, compete with coil and more

importantly the multi-plug lead and a

decent set of HT Leads, all for the

sum of £ 20.00.

Back at the car and with

the distributor all cleaned up I was

ready to install it.

Off came the rocker box

cover and I turned the engine till no.

1 cylinder was on compression, both

rocker arms have clearance at top dead

centre which is marked on the

crankshaft pulley.

I I

remove the old

distributor and retained the old

clamping plate as the new one of the

Fiesta was slightly different.

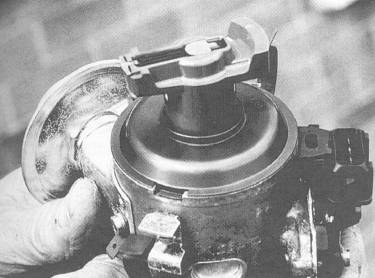

Around the rim of the new

distributor you will find a line or

notch. You can see the notch or line

in the picture at 8 oíclock position.

This is the firing point of cylinder

No. 1. That the front one on the

Crossflow and in case you have

forgotten the firing order for the

Crossflow it is 1-2-4-3. The rotor

runs in anti-clockwise direction as

you look at the top of the cap.

Before you drop the

distributor in, put the rotor arm on

and align the rotor pointing at the

line or notch.

Slide the clamping plate

on and feed the distributor in and

watch how much the rotor turns past

the line or notch. Make a pencil line

on the rim where the rotor is now

pointing. Now make a pencil mark the

same distance away on the opposite

side of the line or notch.

Pull the distributor out

again and turn the rotor to your

second pencil mark.

Drop the distributor back

in and the rotor should stop turning

at the line or notch. You are now on

No.1 cylinder firing position and when

you fit the cap, the rotor will be

pointing at the lead to No. 1

cylinder.

Do not use the lead from

the loom as this is ballasted. Run a

new wire from the ignition switch down

to the positive side of the new coil

(SW15) and join the black wire from

the multi-plug to the same. The green

wire from the multi-plug then fits on

the negative side of the coil with a

feed from this, to your electric

rev.counter if youíve got one fitted.

The third wire is brown and goes to

chassis earth.

All ready to switch on.

The distributor should be fairly

accurately timed up to start the

engine and when running at tick over (

850-900) a setting between 6 degrees

before TDC and 11 degrees before TDC

should suit depending on your cam.

A try out on the road and

make adjustments a degree or two at a

time to see how it behaves. If you get

pinking on hard acceleration, then

back the distributor off a degree or

two.

And there you have it, a

electronic ignition system for about £

20.00 for a fraction of the cost.

I did buy and new

distributor car and rotor arm, but

these are peanuts. You may also find,

depending on your manifold that the HT

Leads to your "top entry cap" foul the

manifold but you can buy side entry HT

Leads to over come the problem.

CHRIS LAYCOCK.

|