| Search |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FITTING TUBULAR WISHBONES Having now put the five-speed gearbox conversion on the backburner for the time being, I now wanted a winter project for the good old Locust. Something to get me out into the garage on a cold winter night and up to my armpits in engine oil a grease.

Casting my mind back to July 2003, on a "run" out with the Club, into the Heart of the Kent countryside to visit the "Darling Buds of May" car show,prompted a new project that would fit the bill. After

leaving the above car show, we had cause to visit

a lovely county Pub (

as you do ) and have a beer. ( only one, drinking

& driving ) Yours

truly got stuck on the exit out of the car park

with the front cross

member scraping on kerbstones between the car park

and the road. After

backing off a couple of times, I managed to get

the Locust back on to

the main road. Now I have always had a very low

front cross member. (I

will wait for the laughter to subside) The front

suspension on my

chassis, which is the White Rose vintage from

around 1996, has the

Cortina set-up. As the car has been on the road

for some 3-4 years, the

front suspension has "settled", leaving the Front

cross member about 2"

clearance off the ground. The only way to increase

the ride height was

to put spacers under the coil springs or longer

springs in order to

push the front up, but this is a hit and miss

affaire.

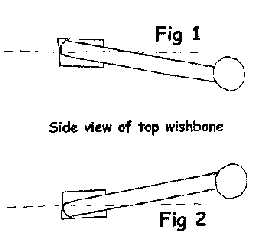

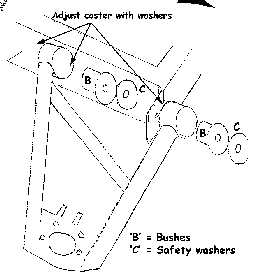

Pre

White Rose chassis has the suspension "towers"

made from box section,

like the chassis rails. Measurement for this

should be 260mm and mount

the top wishbone as in Fig 2.

8 Ford new bushes from a Cortina Part No. 6009975 were pressed into the newly painted top & bottom wishbones, using a large vice and large 32mm sockets. The large angled flange bracket which held the tie-rod was cut off using an Angle grinder, as this was not required and so was the rear bracket from the old front tie rod bracket.

Two Top Ball joints from Ford Transit van & Two Lower Ball joints from Ford Cortina are required, with the angle flange cut off the lower ball joints, which are then bolted from the underside of the bottom wishbone.

1.

Chock up the front of the chassis to achieve the

required ground

clearance, using 4" x 2" wood complete with hubs,

steering rack and

wheels. I was aiming for 4" ground clearance under

the front cross

member.

Next to buy was the 1.9" springs. What is the correct spring rate when fitting coil over suspension. There is NO exact answer to this. It will depend on several factors. I understand that when WRV first started selling the wishbones, they advised the use of 150 lbs springs and updated to 180 lbs. I went for 150 lbs as the springs can be stiffened up using the adjustment spring pan rings.

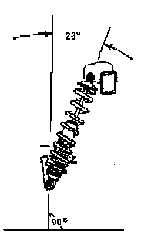

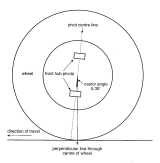

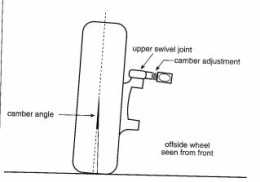

The ride high under the front cross member was now a tad under 4" after winding up the shock absorber spring adjustment rings to about half way up the threaded part of the shock. The camber angle was now set at 0 deg and the "toe-in" at 0.05 deg by using a tape measure,( this was checked a couple of weeks later by a Tyre company to be actually 9 deg of "toe-out". So much for using a tape measure. The camber angle was spot-on.) and after checking all the nuts and bolts have been tightened up, new split pins installed through the Castle nuts.

So out for a test run, and as it was in middle of February ( and YES the car is Taxed, MOT ed and Insured) so it was only a quick trip round the block to see how it would respond. A quick test on the brakes, and the car pulled up in a straight line. So far so good. Up to the T junction and a left turn, and immediately I could feel the steering wheel trying to straighten up. Not strongly, but just like a normal car should be. Next test was a few bumps to test the suspension. It felt a little stiffer than with the old set-up but apart from that, all felt good. The best part, was driving the car back into the garage, as a 1" high lip in the concrete had always "grounded" the car halfway down the chassis. The only way to get the Locust in, was to lay down scaffold planks and drive into the garage on them. No problems with the new set-up. Was it all worth it in money terms. Well, here's the costing

A

lot of money, but the car handles better, look's

better, the suspension

is more "tweakable", steering wheel self

centres, goes in garage and

better still, not likely to "lose" the sump when

going in Pub car

parks!!!!!!!!!!  Happy Locusting............ Chris Laycock. Many thanks to Phil Manship for his very useful information, both written and verbal on the above project. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|