| ||

| Search |

|

It all began in November 2003 having got a buyer my fully prepared autotest mini and the search started for a seven type kit car to replace it with. I had about £3500 to play with and out of that I had to buy the car, and fit it with an LSD if it did not have one. Now

the problem was I am nearly 6ft 5ins and 16stone so quite a large frame

to squeeze into a car. I did the usual looking on Ebay and having a

look through the ads in kit car magazine, but everything was so far

away, and it was an awful long journey to find out if I would fit in it. In November I spotted an advert with the Whiterose Locust advertised for sale, unfinished rebuild project for £1650 and in Richmond, North Yorkshire. Well at that time I worked in Richmond and having spoke to the chap about it on the phone and explaining what I wanted to do with it he thought that it may not be the right machine for the job…i.e. a bit heavy. As I literally passed his door every day I decided to call in for a look anyway, it would not hurt after all and so after work nipped to his house. Upon seeing it I loved the look of it. It was as it stated an ‘unfinished project’ but looked not to far away, needed the cycle wings fitting, painting and daft things like front indicators and other bits & pieces, but it ran and drove. I said that I was interested and would like to call back with a friend to have another look. That Sunday I returned with Phil, who is a fellow autotest competitor, but knows a thing or two about kit cars, and would be helping me in finishing it off and preparing it to race. Unfortunately what Phil did not realise was what he was letting himself in for!!!!! So when we arrived Phil started looking around the car…..mmm 5 link back axle with some coilover type suspension….and not horrible leaf springs. The work that had been carried out was to a very good standard, which pleased him, and being a body shop manager for a large rental company he knew good workmanship when he saw it. So the checking of the car continued, the engine and its twin 40’s burst into life when asked, and the engine transpired to be a tuned xflow out of a Mk2 Escort rally car, but more on this later. To the front the suspension was the usual Cortina wishbone setup, and we knew that could be changed anyway. So after a few quiet words with Phil I had a chat with the owner and the deal was struck at £1550. I collected the car one evening and as loading onto the trailer noticed that the wheels turned more to the right than to the left….oh well I thought that will need sorting, and brought the car to what was going to be its new home. So really the first thing was to see how it went and what I had bought. Some work was required to enable me to do this and I promptly set about getting this underway. First thing was I needed an LSD (limited slip diff) to enable the car to donut round the cone. With it having the Escort or Capri back axle the diff I needed was a common one, but even still finding one for the right money was proving troublesome. Ones on Ebay were making strong money and you did not know how worn they were. In the end I bought a brand new one at £485…ouch. So with that one sorted the steering needed looking at, the reason was the rack was not centred with the car, and there was not enough adjustment on the track rod ends to take this up. Now I don’t know if this is a Locust build problem but in the mini I had a quick rack fitted. 2.2 turns lock to lock and it was worth the while, so I thought I would do the same to the Locust and ordered one, but with it modified so the wheels would have the same lock left to right. This totalled nearly £200. Worth the money……..? I don’t know yet. The original bonnet had a hole in the top where an air filter would have poked out. This was no good, so a new one needed to be sourced. After doing some research (I was naive with locusts at this point) came across that I needed to speak to Bev at BWE. Now the previous owners had tried to get a bonnet made before, but for some reason encountered problems. I found Bev great to deal with, and he even came and met me half way to save me a long journey…now that’s above and beyond the call of duty. The final job was a rolling road session. I did not know if the engine had been set up and carbs balanced so in it went. The phone call came and the news was not inspiring. There was leakage on the valves, the manifold was restrictive, loads of backpressure which threw engine oil everywhere, bad compression on no 4 piston…….oh no I thought. With the news as it was, I contemplated not attending the practice day, but thought well it runs and took it anyway. The car was blisteringly quick in a straight line; my driving was rusty in RWD but eventually sorted myself out. As the day went on, gremlins and faults appeared, but that was what this was all about. The cam appeared to be a spec for rallying; kicking in at 3000rpm so that was no good. I knew the engine was not great, and realised work was going to have to be done. It tramped badly when reversing and the handbrake was not really as good as I would have liked. Between Christmas & New Year there was a proper event, so along went the car again in a largely unchanged format. The day was cold and it had been snowing. The venue was some industrial factory and out of the two tests that were on one was covered in snow and the other was full of dirty silty water. The day was hard to enjoy as with the car having no grip on one test and getting pitted with crap on the other because of no arches to the front I was getting fed up, and to cap it off the window wipers gave up….pah With the car back at home I had to decide what to do. The car needed to be painted, and the cycle wings fitting. Then there was the question of the engine. So along came Phil again. At the time I did not have a garage and the car was kept on the trailer at my parent’s house under a tarpaulin. This was not the best scenario in the world for working on it. Phil however had access to a major vehicle leasing workshop. Light, heat, space and got the clearance needed to do some work on the car and also for me to be onsite as well.

First job was to remove the engine from the car, and was easily done in an evening, and then work began to prep the car to be painted. Phil worked hard, getting the cycle wings to fit and doing all the other jobs on the bodywork which that was needed, the car was stripped in no time and then it was a case of Phil painting the car, all I got to see was some pictures emailed to me. The pictures were great, and just could not wait to start to rebuild the car again. The second plan of attack was to sort the engine. Another cam was purchased from piper which was more like what I needed and following the valve problems discovered at the rolling road session we tackled that too.

Working in Phil’s own garage this time the engine was stripped down. The new cam was fitted and the valves reground into the head. It looked like the bottom half of the engine was recently built with the shiny pistons we could see. Apparently when the guy who was doing the rebuild of the kit car the engine was In a mk 2 escort and it took off like a bullet from a gun, so things looked pretty good in that department. Once the engine was finished being tinkered with it went back into the car, and one sunny afternoon the rest of the car was rebuilt. It sat on his drive as we fitted all the arches and so forth, with Phil’s son and mate been lured in too. Everyone who walked past commented on it and we even got one guy screech to a halt to come and question us about it. He knew exactly what it was. After a couple of hours there she was all gleaming looking very different as to how she set out. Then on the trailer and back to my parent’s house.

Back to the rolling road again and it was still blowing oil everywhere, the timing was out which was easily corrected by them. It also was getting very warm which was strange as it never did that before. So home it came ready for its next outing at an autotest. We put on a breather system into a catch tank to hopefully resolve the back pressure, and things seemed sweeter with that fitted. Off we trundled to York…well Rufforth air field for the day, the car went through scrutineering ok and on to the test we went. It was ok, but the handbrake was still not to my liking and to get the car to slide and spin was hard work on the grippy surface. As the day wore on problems crept in. The oil was pressurising still in the engine, and forcing it out of the sump gasket, leaving a trail of oil. The water system was pressurising and boiling up which was odd as the car was fine previously. Phil retired half way through the day the save the car and I soldiered on. We finished the day and headed home…..some more work to do. I was beginning to think I had bought a lemon….really down hearted about the car and just kept thinking of the money I had invested into it. We toyed with many ideas and looked for another head for the engine, but I was not happy with it, that back pressure thing was still worrying me. I was leaning towards a full transplant of something a bit more modern, and after many discussions with Phil we decided to go for a Zetec and then the search started for an engine…..but it had to be a good one. I was bidding on a couple of complete cars on eBay but lost out on them, and did a deal on a focus engine which had been shunted from behind, the deal was done and we awaited the arrival of the engine. It did not arrive. After an irate phone call he apologised and said would organise another delivery, after all it was coming from the south coast. On the second delivery day it did not arrive, and I just ended up getting my money back…the search started again. While at work one day my phone rang, it was Lee a fellow competitor who was a mechanic from Newcastle. He knew of an Escort going which was an MOT failure but Zetec powered and with 50k miles. So the deal was struck at £200 and off I trundled to go and collect it with the trusty trailer.

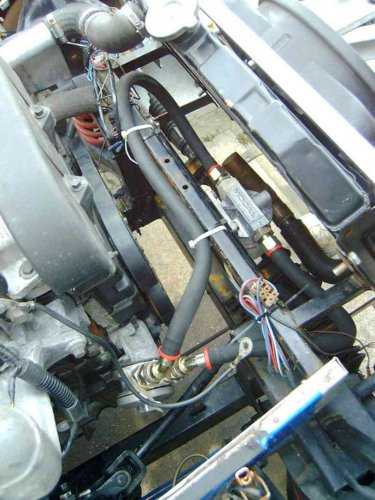

So with the Escort back home the crossflow was placed on the internet for sale along with the Webbers and ancillaries. A price was finalised at £205, so that was the Zetec paid for!!!!! It was removed from the car for the last time and was not sorry to see the back of it, but did not realise what was going to be involved in the fitting of the new engine. Phil took the Escort away and promptly brought it back with its nose pointing into the air, minus an engine, and the empty space in the engine bay of the kit car called. The next job was to find out how the engine was to be linked to the type 9 gearbox. The first intention was to put an MT75 gearbox in but the physical dimensions of the gearbox would not allow the installation without a major reconstruction of the transmission tunnel, not a job we wanted to undertake. So with the engine being the 1.6 16v 90bhp motor it was deemed the type 9 would be able to cope with it. Upon surfing the net one night an invaluable website was found which stated exactly what needed to be done to mate the two together. (More on this in a separate link to follow) With a new clutch purchased (the new one in the crossflow would have been suitable) the job started to install the engine into the Locust. This fell within the domain of Phil and with the car at his works, and a change in management policy much to my frustration I was not allowed to be onsite, so Phil kept me up to date with progress and worked towards getting the engine mounted within the confines of the engine bay of the Locust. After a phone call to Phil he confessed to having ‘the bit between his teeth’ to get the engine mounted and in. True to his word he did it, and later that weekend the car was returned with its engine in place. The finishing off of the engine took quite some time with projects being embarked upon by myself and Phil, so the forthcoming descriptions may not appear to have happened as seamlessly as they are written Phil always had the opinion that the physical mounting of the engine was the easy bit and everything else was going to be harder, but that came onto me….to a certain extent. With the engine mounted now I had to add the ancillaries, first off was the alternator, the standard item was retained as it located itself perfectly with the pulley for the water pump and tensioning pulley. The wishbone had to be ground away a bit to give a clearance of 4 -5mm and the mounting for the flexi hose for the brake calliper had to be lowered, other than that it was in. We also fitted a hydraulic handbrake, with a vertical lever. This proved to be a pain with certain parts of the piping weeping sometimes, blood sweat and tears with a few swear words thrown in it was finally in and working, that should solve the handbrake problem. The mechanical handbrake has been retained for the MOT as it is going on the road. The original header tank was not to my liking mainly because the return pipe had been chopped and blanked, so from a fiesta which had been purchased to fill an autotest gap and fulfilled its purpose (which donated its engine to a friend’s Suzuki SJ for off- roading) donated its header tank to the kit and was fitted utilising the original header bracket Next was to get a belt to join all of the aforementioned pulleys together and spinning in the right directions, a trip to my local Partco with an approximate size soon came up with a belt suitable, this was then fitted. Next job was the oil filter. The one on the Zetec is at the right hand side of the engine towards the front so it coincided with the steering column. Oh joy. Again back to Partco with a maximum length it could be, and returned home with a Renault one that was the perfect length as not to interfere with the column, but alas the threads were wrong and it was not to be. So the solution rested with a remote filter, with a fitting being screwed in place of the oil filter with off takes that enable you to pipe to the filter housing which is fitted wherever you want it. This was purchased from Burton Performance at a cost of about £70. Next up was to mount the coil pack, this was rather close to the drivers foot well, but with some careful grinding of the mounting bracket the original mounting was retained and fixed in place. Another of Phil’s Job was to fabricate an exhaust manifold. I bought a flange and collector pot, while Phil got some exhaust tubing. He had access to a pipe bending machine at work and promptly set about making the manifold. The initial results were heart wrenching for Phil, as getting the required radius on the pipes was proving difficult with the pipe kinking, however perseverance paid off and he managed to fabricate the mother of exhaust manifolds that would lend itself to the overall look of the car.

Next on the agenda was cooling. Again thanks to the tinternet a diagram was found illustrating how the system had to be plumbed in. As my Locust was not running a heater I modified it slightly, but utilising existing pipes I had, got the bulk of it plumbed in. But was lacking one or two fitments. These were sourced from a ford dealer and a scrap yard, only because the originals were worn or damaged. My wife’s dad supplied me with some aluminium tube which was the perfect diameter for the piping, and in all the whole of the cooling system cost me about £15. Work stopped on the car at this point for some considerable time, due to myself installing a garage and sorting the garden out so it did not resemble a Somme anymore and Phil went all light headed and bought a Marlin that needed an engine transplant, so his time was largely taken up with that……Phil’s Mrs recons the Marlin is prettier but I don’t think the shape of a seven can be beaten. Mind you the camera would not let me get a picture of the Marlin…….cant imagine why Next up was the wiring……ha ha. As I was keeping it on injection this was out of my hands (even if I was on carb's would still have been) so in came Tony, another friend. We originally thought that the ‘red’ key was going to have to be retained, and placed in the reader which is located around the ignition of the ford, but after he had loosely wired everything up (after removing the loom from the stricken Escort about 6 months ago) got it turning over bit that was it. What we needed was the clock from the escort to show us that the immobiliser was disarmed, but it went with the car to the scrap yard. By a stroke of luck we got it sparking, only for him to return to find it would not. By a stroke of luck he was looking into the loom to see what the problem was and discovered how ford were immobilising it, he promptly ripped this bit out (which turned out to be quite a lot) and we junked the whole immobiliser thing to be left with the bare requirement. Bish bash bosh and it was sparking, but the fuel pump I had bought was not working so he said he would need to return when I had sourced another. A fuel pump (off and injection car) so it had the right pressure was sourced from a local breakers yard and promptly tested before I parted with hard cash. Back at home a make shift petrol supply was fixed up and Tony informed so we could do the initial start up. Once the petrol had made its way through everything it started straight away, albeit not sounding so healthy, but it was running. This was deemed a milestone. So from that point Tony hard wired everything, and wrapped everything up in insulating tape so it all looked neat and tidy, running of the car at this point was done by balancing a gallon petrol canister on the top with the feed and return poked into the top, and tugging on the accelerator cable It was lumpy and reluctant to rev so blanking the vacuums off helped a bit as this was unmetered air, but it was all going to have to come off as it stuck up too high for the bonnet. Work stopped again as I had no electric in the garage and the dark nights of 2005 were creeping in, oh and the better half wanted the bathroom redoing…….a mans work is never done. Just before Christmas 2005 the miracle happened and the garage had power and light, the festivities came and went and then the plan was hatched. While at the Christmas autotest my absence was noted, I had arranged to borrow a friends Nova but the snow that had graced us at that time did not agree with my BMW, so I decided not to risk bringing the car out, anyway it was New Years Eve and an evening of drinking was planned!!!!!! Phil made the bold statement that the car would be out by March, and with Christmas and New Year out of the way we had the bit between our teeth big time. The car was removed from the trailer and placed alongside it in the garage (spoilt bugger I am with a big garage) and chocked up on axel stands. A list was compiled of every mortal job that we could see that needed to be attended to, and it also allowed us the plan and schedule everything.

My job was to mount the fuel pump and filter, and the finish off the fuelling to the engine, not a hard job with the car sat in the air. Then all of the pipes were clipped into place, and the wiring routed to it and tidied. My other friend Mark whipped out the petrol tank ready to give to Phil so he could braise a return on. With it running on injection it needed this, so that was carted away by Phil one evening. One of the major jobs that needed to be done was the new inlet manifold. Way beyond my capabilities this was, but had acquired a spare inlet manifold for Phil to do with as he pleased. Buried away in the depths of his workplace he forgot about the outside world……his wife…..the price of petrol and set about fabricating this major component. He got some materials together and made a flange, and just got some pieces cut then popped back through to mine so we could see what had to be done. Now the components consisted of a former prop shaft from a transit, and the leftover exhaust tubing. It was all offered up to the zetec, discussed, chopped and tacked into place then removed for him to weld up properly at work. Another flange was made to go on the end to mount the throttle body, and then we discovered that the air bypass valve had to go in, and in such a way that it kind of scuppered the original plans, but Phil was not phased by this setback, and designed a solution by mounting it at the opposite end of the manifold to where it really needed to be, but ran a pipe through the middle of the inlet manifold to link the bypass valve and throttle body together, this will allow it to tick over. While messing on with the inlet manifold, we knew that the air flow meter had to go in somewhere, and realistically needed to be towards the nose cone area to draw in cooler air rather than hot air from the engine. This was not a real problem in itself as there was room for it but we could not get the pipe past the radiator, so the radiator was moved over 35mm to allow the clearance needed, just hoped my dodgy welding would hold!!!!!!!!! Phil returned once again one Saturday morning with petrol tank and what looked to be an impressive looking manifold, which looked as though it had been bought for the job. The tank went in, and all piped up….lovely job, and the inlet manifold was fitted and it was the moment of truth. One problem was encountered in the form of……(he is gonna kill me mentioning this) that when all of the wires were removed from injectors and so forth Phil was stating “the beauty of fords is that all the multi plugs are unique and you cant get them muddled up, I got bitten once by a Peugeot that…….” And guess what……yep they were not individual so we stuck out fingers in the air to see which way the wind was blowing, and fitted them back as per there length of wire and where they reached. The car started and sounded ok so we were happy at that and left them alone. Once Phil got home he was able to check the wires on a car that had been untampered, and we had got one right, but no big issue to sort them and Phil then bandaged his arm where the big bad locust had bit him!!!!!! We were really motoring and the season started again on February 19th and we were looking well on course to get it ready for then. A cradle was made to mount the ECU under the dash, and a hole drilled in the bulkhead to allow the loom through with the grommet and with that done it was all fixed nicely in place.

The end was in sight, the brake callipers were binding and Phil whipped these off and took them away and stripped, cleaned and rebuilt them. We offered them back up to the car bolted them on and bled the system; cor we could now push the car….even with one hand.

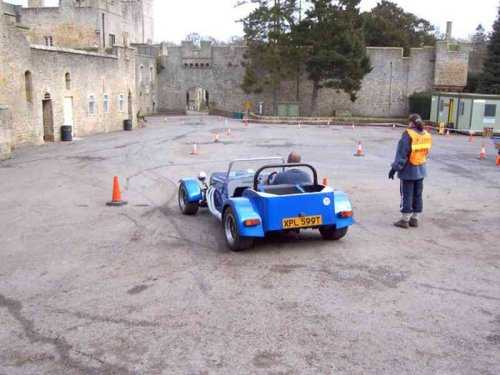

Things were almost there now, some checker plate was acquired to line the back, and my friend got the roll bar powder coated for me. We glossed all the inside black and with the chequer fitted and roll bar done it was all starting to look ‘bling’ Because of the blistering pace that the car had been finished off we were well within our timescale, and when the car went out for the fist time we wanted her to be as perfect in presentation and performance as we could get her. Phil took 4 wheels away with him, and prepared them for painting. Once they were prepared he painted them, put the tyres back on and brought them back, and then took the other four wheels I had away and did the same with them. I need spare wheels when autotesting if the tyres that’s on ware out or worse case I hit something or puncture them. So now I had 8 wheels that all matched and looked the part. So with the car now as ready as we can get it, it was down to the professionals to just finish it off. The car was booked into Teesside Motor Factors (incorporating tech tune) 01642 232222 for a rolling road set up session. I arrived at 8:30 on the morning dropped the car off, and put my trailer into the car park which was promptly penned in and left it with them, and set off to work. My stomach was churning because I wanted it all to go so right, and every time the phone rang it was promptly pounced on in case it was them. By lunch my nerves got the better of me and called them. “Ah hello Mr Thornton…yes he’s just on with it now, he’s found quite a bit so best off calling back a bit later when he can go through it all with you…….” Oh bugger I thought. When I called back later, it was all laid bare for me. “Well there was leakage on the inlet manifold so we have been trying to solve that one really, and then when we get that sorted we can do the rest of the checks. What had happened was that when the manifold was made the flange got very hot and distorted, also there were tiny pin prick holes in the welds and all this was allowing un-metered air into the system. They sealed the welds, and fabricated a rubber sandwich gasket to go between the flange and head to seal any leaks and allow for the distortion. Now the other thing that came to light was the injector seals were leaking, so new ones were needed, and another problem was that the fuelling was very lean. I was told that if the car was driven hard it would hole a piston….and that was the last thing I wanted. The fuelling aspect was put down to the lack of a Lamba sensor in the exhaust; this monitors the outlet gasses and tells the ECU to increase or decrease fuel etc. Apparently when the car is started it searches for all the electrical sensors and if one is not present or faulty it logs a fault code and can put the engine into limp home mode which restricts it, and causes loss of power. Some three days later I collected the car, and was told that the injector seals needed sorting and the lamba sensor needed to go in, but the good side was that the car was much sweeter than before. It was provisionally booked back in for the next Wednesday (the event was the following Sunday….despite our great progress this was going to be tight. Seals were fitted, and I decided to do them all, no point in just doing half a job so that was all 12 of them, and sourced a lamba sensor complete with loom from a scrap yard, ford wanted £110. Once I got home I had a look for the plug in the car to just plug the lamba sensor in, but it was not there. It was a good job I had the whole of the plug from the one in the scrap yard. Tony the auto sparkie called back round and delved into the loom and picked out the wires that were needed and the plug reinstated. Phil mounted the sensor into the exhaust, and then started the car, and it seemed a whole lot sweeter to our ears. Back to the rolling road, same scenario as last time every time the phone went I thought it was them. Anyway when I called the news this time was more inspiring. They had found a couple more air leaks, changed a pressure regulator in the fuel rail to increase fuel to 3bar and he said he was very happy with it. Because the wheels were only 13inch we could not get a reading off the dyno as the chassis rails were hitting the ground and making the car jump all over. But I was not worried about that as the thing took off from nothing and just wants to light up the rear wheels. Back on the trailer and homeward bound, ready for Sunday. I was so relieved that we had made it, god knows how many hours we had spent on it but the end result was worth it, however it was in the lap of the gods how it was going to go. Witton Castle – 19/2/06 We arrived at the test in good time, unloaded and signed on. There was a perimeter road and could not resist a blast around the outside, tail snaking it struggled to get the power down onto the wet surface but the fun factor was great.

So this was it, sat on the line ready to go and my memories of this car from the last test were not great. “In your own time Mark” the timekeeper stated and boom, I was off. The handbrake was crisp and the power was there. It all seemed to work well, stop at the finish and I thought excellent. Pulled off the line and it boiled and spat water on the deck………oh no was this the way the day was going to go. The fan had not cut in, so armed with a staple, bridged the fan switch, on the fan came and that was that disaster dealt with. Second go and when I crossed the finish and pulled off I heard Mark shouting stop to me, I was leaving a trail of oil………upon investigation one of the fittings on the remote filter was leaking. A spare jubilee clip was found and that solved that one. Other than that the day went without fault, Phil broke his Marlin so ended up driving the Locust all afternoon and the car took two drivers no problem. It did begin to misfire, but not badly and the day was completed. The end result was 5th overall out of 14, pipped by 4th by a mere 2 seconds, but I was happy with that. At home some new leads were fitted, along with a new fan switch and an override switch installed, along with a new thermostat. Hartlepool town centre – 26/2/06 With the car going so well the week before I had high hopes for today. Hartlepool event is wide open tests, very grippy tarmac and a real tyre shredder, along with a car tester. The first test and just looping the last cone the car died and had to be pushed off. We thought we traced it to a faulty connection on the starter, and got it going for test two. It sputtered to a halt in the same place again, but sounding more like fuel this time. We removed the fuel pipe, and tried the pump. Some petrol trickled through but not at the correct pressure. We found a cable tie on the return pipe that looked to be squashing it so unclipped that one and it fired into life. This happened once more as the day went on, and is something that will have to be looked at with time. While doing a 360º donut another pipe blew off, this was most spectacular as the oil just blasted out of the engine, all over the floor and down the side of the car, quickly I turned off the car while marshals dealt with the spillage we wheeled the car off to fix, it was done in 5 mins and sorted after borrowing some oil, as on inspection I appeared to have lost nearly all of mine!!!!!!!! On the third last test of the day was mid flight on the test giving it big licks, threw the line perfect, rear wheels over, but not the front and was foot down to get away. But my foot hit the deck and that was the end of my day, snapped throttle cable. Sick of the problems, feeling full of man flu and freezing cold I went home. Stuck it in the garage and went to bed. Next outing is 12/3/06 and have got a new throttle cable, engine oil as what I put in was a bit thick and just need to prep it ready, let’s hope this event is a bit better, but its all about development. Has it all been worth it?? Yes, I think it has. The end result is good. The car has good power, and the engine is much more modern, able to run on unleaded and just is much more refined. Thanks This whole project could not have been done without the help of one person – Phil. So Phil, thanks for all your hard efforts…and to Mrs Phil for her patience while he has spent all of his time on my car, lets get out there and have some fun with it. Big thanks to Mark as well who also committed his time to the project Cheers Chaps.

| |||||||||

|

|

|