| ||

| Search |

|

|

This

build report is taken from an article in the January 1992 magazine

CAR BUILDER.

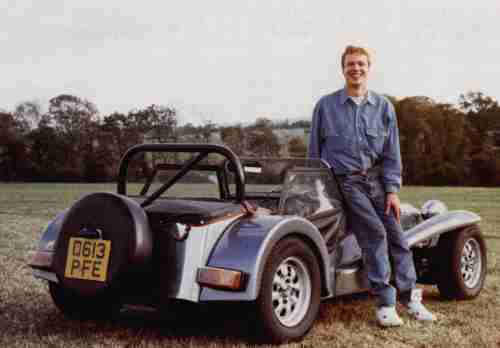

A manufacturers claim of £800 on-the-road seemed a little on the optimistic side, a more sensible budget of £3000 has achieved a very smart little roadster Richard Mann is the person responsible. Something like the Newark Kit Car Show can be very frustrating when you're just out of school and your pennies are worn out from being rubbed together Richard was nineteen when he went to the 1987 Newark show. Having been interested in model making, the thought of building a proper car was really not too wild.. Taking on a job as a machinist was also a good move. He noticed the JC Locust at the show and was interested by the £800 on the- road estimate advertised by the company. Luckily he didn't believe all that he read and came up with the sum of £3000 for a decent quality build using the Locust plans and lots of elbow grease. Surprisingly Richard's dad was very much in favour of the project but his mum had a word or two to say. It looks like her historic order for a poodle had to be honoured if the Locust was to get the go-ahead! September 1987 was the auspicious date when the Locust and the poodle started arriving. The poodle arrived all in one go but the Locust didn't. Its engine was the first main purchase a standard Escort/Cortina 1600 X-flow That was it, the plans had to be ordered now that the engine was in the garage Smart move Richard. Mr Mann had bought his first car only nine months before the Locust project and although he had been a witness to his father's car maintenance operations, he hadn't really partaken of them before. The plans were ordered while the Locust was still under the wing of John Cowperthwaite's JC Sportscars. A few weeks after they were ordered, they still hadn't arrived. A quick 'phone call had them on the doorstep the next day Having studied the plans for a while the first big outlay was for the steel chassis. After all, you've got to have something to bolt the alloy-clad wood and GRP mouldings onto. Very few plan-car makers end up welding up their own chassis. 'It really has been sent' was the JC response to enquiries. So it had. it just spent six weeks in another ethereal plane somewhere between JC's premises and Richard's home in Retford, Nottinghamshire. Funny how these delivery companies are always to blame, not the manufacturers. Richard recalls that the trailing arms for the live axle arrived some days later and selected other pieces arrived in their own good time. Never mind, it was all ok when it eventually got to Retford. Storage space wasn't such a problem as Richard had decided to get bits separately instead of bringing in a donor vehicle. The £60 Ford engine got a rebore and a gearbox and axle cost £20 the lot. Steel wheels with tyres were found to help keep the rolling chassis mobile. All other parts came from a selection of vehicles. An Escort loom, Rover handbrake and the heater and

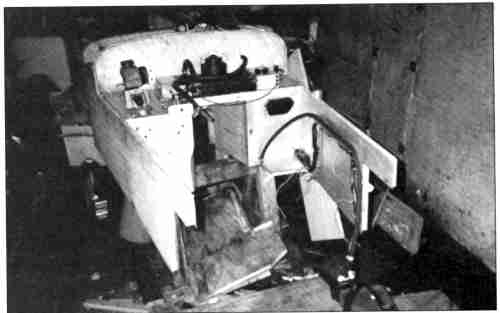

Above: This is the body prior to fitment onto the chassis. The basis for its construction is aluminium clad' wooden panels which combine to make a very strong yet cheap to build structure.

Below As above but fitted onto the chassis. tank from a Spitfire. As ever with this kind of kit, modifications were necessary to shorten the propshaft, lengthen the steering column and alter the Herald pedals. The pedals needed shortening at the lower ends and lengthening at the upper ends to poke through the ply bodywork. This, as Richard was to find out considerably reduced the original mechanical advantage and made for a heavy clutch action and slightly reduced braking power Nevertheless, it also meant a quicker throttle action, no doubt. Surprisingly enough, Richard reports no major problems with the build-up. Many have come to perceive these plan-built cars as genuine tests of initiative, enthusiasm and manual skill. it looks like most everything went where it was meant to without a great deal of fuss. It was 'rather tricky' modifying the Escort loom to fit the Dolomite gauges and the bonnet had to be curved by hand, with the aid of a six-inch diameter drain pipe section. First attempt wasn't too successful -- a kink around the carburettor aperture -- but the second try was remarkably good, 'using a template of the nosecone and bulkhead'. Unfortunately the build manual was just a bit on the sketchy side after the description of building the wood tub and skinning it with alloy sheet. There was no mention of where to put the lights and no reference to Construction and Use regulations on lighting (or anything else, probably). JC weren't able to answer questions directly when Richard phoned them for advice. Having had a rough ride with delivery dates anyway he became even more disinclined to use JC as a source of information. No matter he was able to sort out all the problems without calling in

Above: Triumph Dolomite instruments were used in the dash. The whole interior took quite some time although a local person helped with the stitching.

Below: The end result more than justifies the time spent. T&J has used the car for demonstrations professional advice I knew how most things should be and was able to manufacture parts to get around small problems. That I enjoyed doing, so they weren't problems to me'. Until T&J Sportscars took over the project starting in 1989, Richard was left to make several things at home. 'The clever idea of using plans and wood was well thought out and proved easy to put together. Headlamp and indicator mounts, wing stays and a rear number plate mounting bar numbered among his fabrications 'Many of the extras I made are now available from the factory'. The homework stretched into the trim job, with the carpet and seats included. Grey and black carpets were edge-trimmed in red and a local person helped with stitching up the leathercloth covers for the custom-bunt seats. The dash also got leathercloth covering. Hand stitching accounted for the gaiters around the handbrake, the dip switch and the roll bar Overall, Richard is pleased with the way that the build went 'The build was quite good and the body went together very well. The clever idea of using plans and wood was well thought out and proved easy to put together'. There was a great deal to be learned in the build process and Richard enjoyed most of it even making the bonnet'. There were a few problems which I expected, but I didn't realise it would take as long as it did and involve so much work'. Sometimes several attempts had to be made to get new fabrications correct. There was absolutely no hassle over registration. Richard was expecting a full car inspection but the standard MOT was all that was needed. In fact he feels that there should perhaps be a tougher test for newly built kit cars (Don't worry Richard, there will be before too long). Adrian Flux and Co. organised the insurance and there wasn't a problem even when the engine modifications were mentioned. A deposit of £30 was required. The engine ended up with a Kent BEF2 cam, twin 40DCOE Webers and a Janspeed exhaust manifold. Out on the road, the Locust performed very well indeed. It pulls very quickly up to a good cruising speed (we can't print what you wrote Richard) and is unnervingly quick around the country lanes. 'A pleasure to drive'. That clutch was a bit heavy until he got used to it and he soon did, with at least 20 miles per day added to the total. After around 8500 miles though, there were some stress cracks in the alloy sheet and it also became obvious that the suspension was too hard, especially at the rear. T&J have suggested 100lb rate rear springs as opposed to the massive 250lb rate fitted. When driving around with Lotus Sevens and Elans the locust holds its own quite nicely but the hot hatches have the edge at top end speeds. T&J have used Richard's Locust as their display car at Stoneleigh and Newark in 1989 and also as their demo for a weekend. In addition to that involvement Richard has also become the Locust secretary of the Moss Owners Club and a member of the Mongrels Kit Car Club at Lincoln. 'It keeps me in touch with news and events and gets me and my car out and about'. Further improvements to the Locust might include a complete change of spring rates when T&J come up with the full specification and the rear has already been lowered 1 1/2" with the addition of a shorter Panhard rod. A new exhaust could be in the offing, as well as a brake servo and a more powerful 160bhp X-flow engine. Would Richard build another car? Yes. He was thinking about a GTM Coupe but figured out that the budget would have to be in the region of £8/9000 for a concours example. That's getting into Cobra money but all choices will have to wait until funds permit. Towards the end of 1990, Richard and his Locust were involved in a head-on collision totalling some 80mph. Most of the impact was absorbed by the front offside and the van involved was written off completely Richard (and, we presume, the other driver) walked away unscathed and the locust got a substantial rebuild. T&J were particularly helpful during this rebuild and speeded things up a lot for Richard. There was substantial damage to the front half of the chassis and also to the woodwork but it was all fairly straightforward to renew after T&J had efficiently repaired the chassis. Stiffer alloy was used to sheet the new wood panels. New trim, new colour for the GRP panels, and a generally smarter overall look. That's undoubtedly proof of the strength of plywood in a car's structure If it had just been a simple ladder frame with non-structural GRP panels perched on top, who knows what the result may have been? The car is now back on the road after a six month repair job and the new Honda Montreal blue for the GRP sections in contrast with polished bare alloy looks a real treat. A very ambitious effort for a first car build, although Richard still thoroughly recommends the experience to anyone who has the time to undertake the many jobs involved. Body/chassis kits too easy for you? Try a plan-built car.

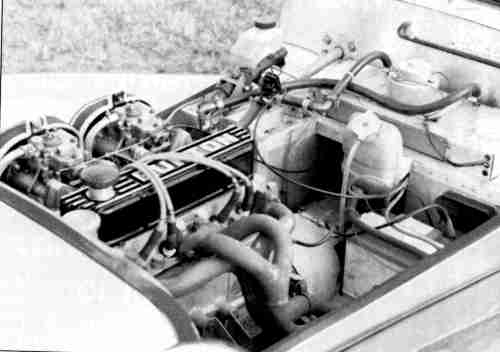

Above: The 1600cc Ford crossflow was rebored and further modifications included the fitment of a Kent BEF2 camshaft twin 40DCOE Webers and a Janspeed exhaust system. All of which helps to provide suitable performance for such a car Below: A recent photograph of the car at Newark 1999 it still looks as good as it did in the above article.

| ||||||||

|

|

|